Helping The others Realize The Advantages Of precision machining

Burnishing is definitely an illustration of a miscellaneous Procedure. Burnishing produces no swarf but is usually carried out in a lathe, mill, or drill push.

Outstanding customer service. I created a comment on Instagram about my lever slipping instead of tightening... down plus they right away strike me up, informed me to email them and they would look after it ASAP.

Ultrasonic machining centres are used for brittle supplies like ceramics, vibrating the surface area and getting rid of small particals. Ceramic resources are frequently Employed in inspection gear for measuring gap tolerances. 4 people today identified this helpful

What Does machining Mean?

The deal with milling procedure can in principle produce really flat surfaces. Nonetheless, in exercise the result normally displays noticeable trochoidal marks next the movement of details within the cutter's end face. These revolution marks give the characteristic complete of the deal with milled surface. Revolution marks can have important roughness dependant upon factors which include flatness from the cutter's close experience and the degree of perpendicularity amongst the cutter's rotation axis and feed route.

Exactly what are the precise devices in machining? The normal precise machining equipment are classified as the centre lathe and universal milling device and for super ending, the surface and rotary grinders

Milling can be a slicing procedure that uses a milling cutter to get rid of product from your area of a workpiece. The milling cutter is often a rotary chopping Device, usually with various chopping factors. Versus drilling, the place the Instrument is Innovative along its rotation axis, the cutter in milling is often moved perpendicular to its axis so that cutting takes place on the circumference from the cutter. As the milling cutter enters the workpiece, the chopping edges (flutes or teeth) on the Software frequently Slice into and exit from the fabric, shaving off chips (swarf) through the workpiece with each pass.

In zig-zag milling, product is eliminated both in forward and backward paths. In this instance, slicing is finished both with and towards the rotation with the spindle. This minimizes the machining time but improves device chatter and Instrument use. Zig full article tool route[edit]

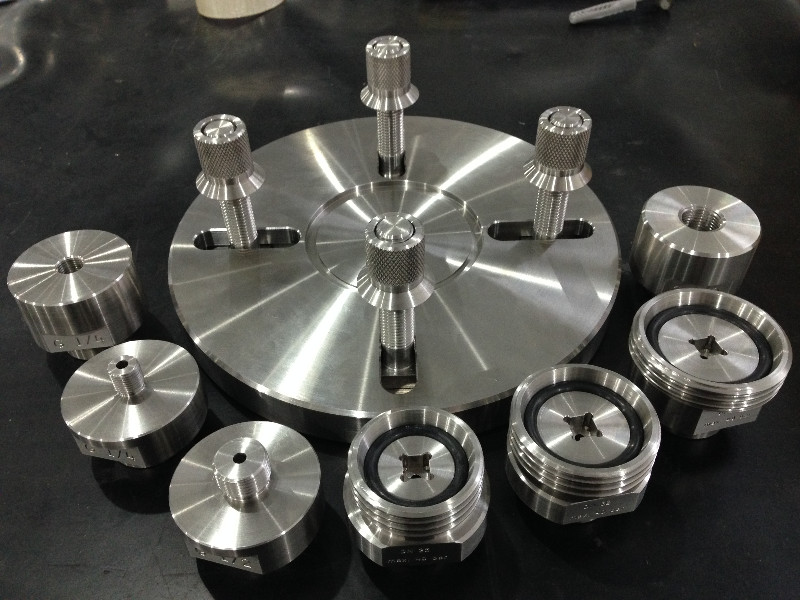

CNC Industries, in Fort Wayne, Indiana concentrates on precision machining functionality-vital ingredient components generally for Aerospace, Protection and Industrial consumers. Many of their consumers are significant international firms. Because of their sizing and very stringent specifications, precision machined elements for this class of consumers may be very demanding.

Detailed Notes on precision machining

What is the noun for precise? The noun type for the adjective specific is preciseness . A associated noun variety is precision.

CNC machines may perform with various supplies from essential aluminum and plastics to additional unique elements like titanium — earning them the ideal device for nearly any position.

A single point Resource has a person leading edge which is useful for turning, tedious and planing. All through machining, the point with the Resource penetrates down below the initial function area of your workpart. The point is usually rounded to a certain radius, called the nose radius.

Over 250 combined several years of outstanding machining craftsmanship combined with the latest technological innovation and most current tactics in lean production support realize the general excellence that sets Orchid apart.

5 Simple Statements About machining Explained

Precisely what is a specific measurment? There's two elements to measurement. Accuracy and Precision Accuracy of the instrument is the ability to get the best value of the measurement. Precision with the instrument tells us how small the variance from the looking at can be. An accurate tape to measure length would give you 5 toes for just a five file…eet size.